Home

Overview

Benefits

Customer

Gallery

G3i

Installation

Instructions

Magneto Harness

Conversion

to

Auto Plugs

MSD

Reference

Spec.

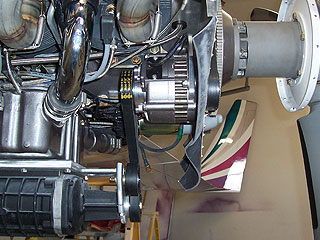

Supercharging

Air/Fuel

Delivery

Dyno Runs

Order

Price Sheet

Contact Us

Generation 3 Ignition “aka” (G3i) is all about aircraft engine performance. From high horsepower demands too fuel economy along with engine efficiency. G3i focuses on designing and developing engine management and performance products from ignition systems to aircraft engine supercharging.

G3i developed the first magneto interfaced-based electronic aircraft ignition control system that interfaces with most Slick & Bendix aircraft magnetos for Lycoming and Continental aircraft engines.

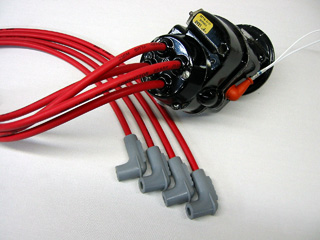

Slick and Bendix magneto harness lead replacement allowing the use of automotive style spark plugs with stock magnetos. Complete harness conversion kits, with instructions to convert one or both magneto harnesses.

G3i Ignitions systems are amplified with (MST) Multiple Spark Technology, which in turns, compliments and synchronizes the firing event in all naturally aspirated and supercharged engines.

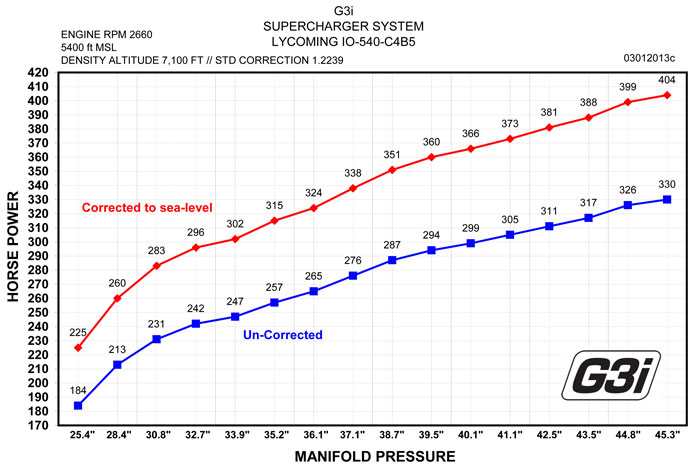

The G3i facility is fully equipped with an aircraft engine dynamometer with full data acquisition, that is recorded to 1ft-lb of torque accuracy, along with synchronized current weather station values. Super flow cylinder head equipment and machine shop to do custom prototyping and testing. Dyno services are available for Lycoming engines, 235 to 540cu. G3i facility Dynometer service can also provide, controlled first run engine break-in's, minor to major modification testing for performance & economy design / custom alterations.

|

G3i News: Click Direct:

G3i Airventure 2013

|

Home Overview Benefits G3i Install Mag Mod MSD Reference

Customer Gallery Spec. Dyno Order/Pricing Contact Us

All work Copyright ©2017 G3I All Rights Reserved